Concrete tie

We usher in brilliant future of domestic railway industry with our differentiated technologies.

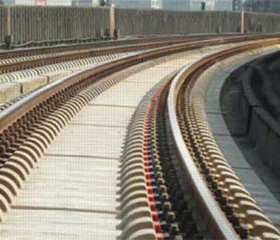

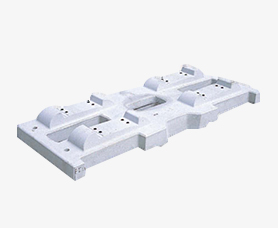

Tie(RC tie) for subway

This is a reinforced concrete tie used in concrete track of railway. It is used widely for subway tracks because it ensures excellent feel of ride and durability due to reduction of noise and vibration compared to gravel track.

Item Name : RC tie(Reinforced Concrete Sleeper)

Type: Delkor, LVT, ERS, STEDEF

Applications: For installation of subway tracks and urban/metropolitan railway tracks

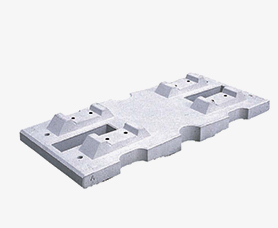

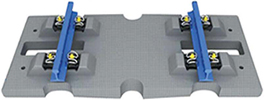

B2S(Ballasted Track To Slab Track System)

This system was developed for the purpose of reducing repair costs in the wake of the increase in track twisting and track bed subsidence on high-speed railway. This system aims to apply the concrete slab track system, which has the advantages of excellent quality, precision construction and easy maintenance, to domestic railways. Our company filed patent application to Seoul Metro for this system known as B2S System in 2006 and has been manufacturing and delivering concerned items for a long time under the production license granted in accordance with the technical agreement that we signed with Seoul Metro in 2008. Currently, the system has been produced as our mainstay product which has gained high recognition for excellent quality and technological competitiveness.

B2S Panel Equipment

- Box Arch : 2,750mm in width

- Single track tunnel: 2,550mm in width

- Fastening apparatus : SMF-Ⅱ(domestic)

- Non-shrinkable charging type motor

- Panel shape enabling the compaction of soil section

- Within the allowable roadbed displacement settlement

- Track gauge adjustment range : +8mm ~ - 4mm

- Fastening apparatus : SMP-Ⅱ(domestic)

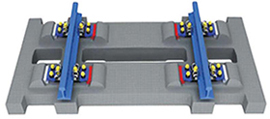

- Reducing the dead load by 23% (3.04tonf/m) compared to gravel track

- Bridge slab panel integration (longitudinal, transverse shear BOX anchoring)

- Resolution of rail axial force: Longitudinal fastening apparatus(fastening force: Zero) applied

SLAB extension 5m limit and separation

- Track gauge adjustment range : +8mm ~ -4mm

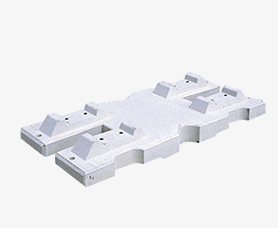

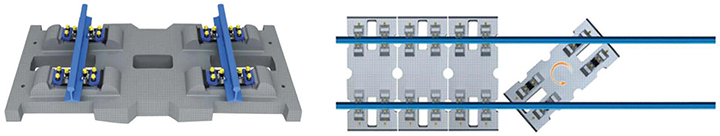

Excellence of B2S Method

Overcoming the short construction time on track line - Average daily working time: approx. 2 hours 30 minutes

- The world's first method for concrete track improvement by using the precast concrete panel

- Rail installation by more than 10m per day (under existing method: 5m)

- Shortening the time taken to complete the track improvement project for line number 1 to line number 4 of Seoul Metro(45 years →22 years)

Excellent quality factory-made product with strict quality control

- Reduced amount of concrete placed on site(25% Down): Ensuring high quality and shortening of work time

Safe and precise construction

- The panel is fitted with nuts inside. The vertical adjustment bolt is adjustable, and the 4 bolts allow precise upward and downward adjustment.

Drastic reduction of noise and vibration

- Reduction of noise from solid materials by 5dB(A); reduction of vibration by 14 ~ 14.7dB

Reduction of construction costs

- Mechanization (gravel suction truck, B2S track machine, mixer trailer)

- Reduction of concrete placed on site: reduction of KRW 500 million in construction cost per km (KRW 2.4 billion → KRW 1.9 billion won)

- Estimated construction cost of tracks: below approximately KRW 900 million/km

Case of Application

We manufacture high quality products with automated production line that we have built, using the latest facilities and systems.